About us

Home » About Us

About Us

A More Sustainable Future, Powered by Nanobubble Technology

Nano Gas™ Environmental develops advanced nanobubble systems that solve some of the world’s toughest water challenges. Communities, municipalities, and industrial operators partner with us to restore wastewater lagoons, recycle produced water, and increase oil recovery without relying on harsh chemicals or expensive dredging.

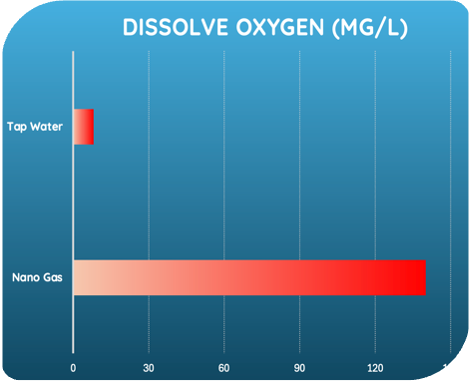

We create trillions of nanobubbles using any gas and inject them into even the most contaminated water, transforming it biologically, chemically, and physically. The result is cleaner water, lower operating costs, and more sustainable operations.

Cleaner, Healthier Water

Nanobubbles break down sludge, reduce odor, improve clarity, and restore polluted lagoons without dredging.

No Clogging - Ever

Our patented generator works even in extremely dirty water, where other systems fail.

Lower Cost & Greater Efficiency

Reduce chemical use, energy consumption, and unnecessary CAPEX with fast, measurable results.

Our Team

Meet our Seasoned EXPERTS

Driven by passion and focused on creating real value for our clients

LEN BLAND

JEFF HARDIN

SCOTT FIEDLER

AL DARZINS, PH.D.

Louis Morimanno, P.Eng.

Our Story

How we’re using this technology to change our world for the better.

Discovering a World-Changing Opportunity

Len Bland had seen it all before, or so he thought. As the CEO of Concept Equity Group, he’d helped secure millions in investment for entrepreneurs with revolutionary inventions. But when he came across nanobubble technology, he thought it was world-changing.

The method was simple yet powerful. By injecting trillions of tiny bubbles of gas into a liquid, one could dramatically alter its characteristics. Len realized how effective this could be as a wastewater treatment solution. And best of all, it was much less expensive and safer for the environment than many other common treatment methods.

Not wanting to miss this opportunity, Len recruited two of his colleagues, Jeff Hardin and Scott Fiedler, and together they started Nano Gas™ Technologies in 2013. Then they got to work experimenting with nanobubble technology to maximize its effectiveness.

Creating Superior Nanobubble Technology

One of the main problems with nanobubble generators is their tendency to clog and not work well in polluted water. The team realized this was happening because of fine porous membranes used to create the nanobubbles. Dirty water clogs the tiny holes in the membrane. To eliminate this problem, the team used an innovative way to create nanobubbles without membranes. Because of this, Nano Gas™ nanobubbles are the best solution available for treating dirty water.

We’ve also broken through other barriers in making nanobubbles. For example, many providers produce bubbles through cavitation, which limits the gases the bubbles can contain to hydrogen and oxygen. In contrast, we create our nanobubbles through a process that enables the use of a wide variety of gases. Our technology also has a multiplier effect that produces 3,500 times more gas than other nanobubble generators.

Discovering a World-Changing Opportunity

With this technology in hand, we were ready to make the world a better place. But we knew we couldn’t be everywhere all at once. So, instead, our team chose to focus on large markets with the biggest value and environmental impact.

The oil and gas industry held huge promise since it produces over 12 billion gallons of polluted water every day worldwide. The Nano Gas™ system makes a vast difference by making produced water reusable in the oil production process. Our nanobubbles have also proven their effectiveness at enhanced oil recovery (EOR) with oil production improvement rates as high as 540%.

When the pandemic put a temporary stop to our oil and gas efforts, we shifted our attention to rural wastewater. The Nano Gas™ system cleans and restores shallow lagoons at a fraction of the cost and much more effectively than conventional bubbling or dredging techniques.

Here are just some of the major milestones we’ve achieved in these industries so far:

- Oil Production Testing with 21st Century Energy Solutions Inc. – The lab results from a 12-month contract showed recovery of heavy oil with dramatically reduced energy.

- Oil Production Testing with Maverick Energy Services – Our field tests significantly increased oil well and heavy oil production without the use of energy-intensive steam.

- Produced Water Treatment with WellKnows – We are currently pursuing major oil company water treatment in South America.

- Manufacturing Secured with Easy Energy Systems – Easy Energy builds modular solutions to solve climate change.

- Lagoon Sludge Removal with Clean Infusion – We teamed up with Clean Infusion to reduce 95% of sludge in rural wastewater lagoons for 80-90% less than the cost of dredging.

Nano Gas™ Environmental

Sustainable Water Treatment for Communities & Industry

Restore lagoons, recycle produced water, and increase recovery without chemicals.