Frequently Asked Questions

What applications does your nanobubble technology have?

Our technology has the proven potential to make a positive impact in several different industries. We are currently focused on three applications: enhanced oil recovery, produced water treatment and lagoon wastewater treatment. However, we expect to broaden our focus in the future to other industries, such as agriculture, paper, mining, food and beverage processing, aquaculture and more.

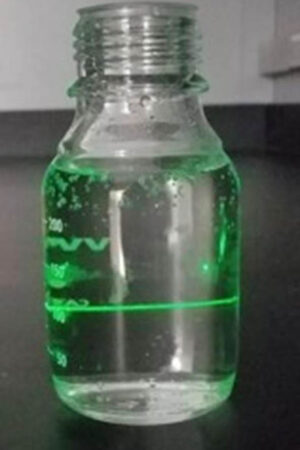

How long does a nanobubble stay in water?

Nano Gas™ nanobubbles can stay suspended in water for weeks or even months. This extended stay allows for a longer interaction period with the water, leading to a more effective cleaning process.

Is nanobubble technology safe for the environment?

Yes! Nanobubbles have no negative environmental impact because they contain natural gases and don’t require any harsh chemicals. Moreover, our technology helps the environment by cleaning polluted water and reducing the amount of fresh water required for its applications.

How does your solution help to save money?

Our nanobubbles have numerous financial benefits for the industries we serve. For example, rural lagoons often require million-dollar dredging, but our automated solution keeps lagoons clean at a tiny fraction of that cost. Our solution is also significantly more affordable and effective at treating produced water than multi-million-dollar saltwater disposal wells.

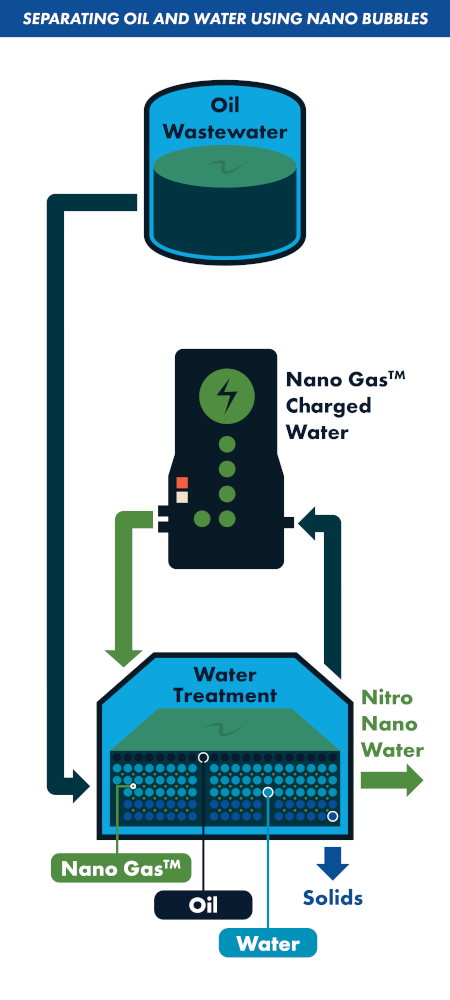

What types of water pollutants can nanobubbles remove?

Nanobubbles can help remove many pollutants from water, including organic and inorganic compounds, certain bacteria and viruses and even some heavy metals. Our nanobubbles are particularly effective at removing oil, sulfates and suspended solids from produced water to make it reusable in the oil production process.

Can your nanobubble technology be tailored to specific requirements?

Yes! We always custom-tailor our solution to solve whatever problem a customer is facing. We can create nanobubbles containing any gas to resolve any type of contamination. Our nanobubble production unit can also generate whatever concentration of bubbles is necessary for effective treatment.

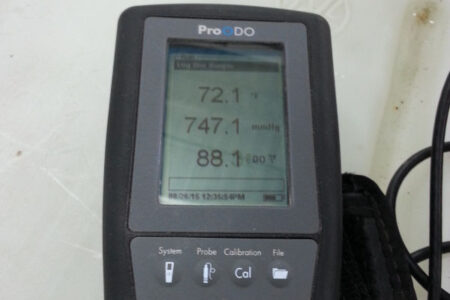

How does the monitoring and control of the nanobubble process work?

Our nanobubble process is automated, allowing us to monitor and control it in real-time. We can maintain the optimal level of nanobubbles, monitor the pH and other water quality parameters and adjust as needed.

Can your nanobubble technology handle heavily contaminated water?

Yes! Unlike most nanobubble production units, our system does not use membranes to create bubbles. As a result, our system will never clog, even in the most polluted water.