Nano Gas ™ Environmental has developed, patented and proven multiple times in the field unique production and application technologies that use nanobubbles to significantly increase an oil well’s production. The most recent demonstration of this revolutionary Enhanced Oil Recovery (EOR) process increased the production of one of their customers wells to 539% of the well’s historical production. The improved production was measured 90 days after the well treatment and is ongoing.

The purpose of this blog is to describe the company’s position in the incredibly important area and their plans for the future. It is organized around:

- What are Nanobubbles?

- Why Do Nanobubbles Enhance Oil Recovery?

- Nano Gas ™ Environmental’s Progress to Date

- Nano Gas™’s Future Plans

What are Nanobubbles?

Nanobubbles are very tiny bubbles of gas that are formed typically in water. Just billionths of an inch in diameter, they are hundred times smaller than the smallest bubbles made with traditional bubbler technology. Nanobubbles are so small they cannot be seen with the microscope but will reflect a laser. As a result, they have unique chemical and physical properties and work in ways conventional gas bubble solutions cannot. They also can reach remarkable levels of concentration.

Nano Gas™’s technology produces over two trillion nanobubbles in a gallon of water. Unlike conventional gas bubbles, nanobubbles do not readily escape from their solution. Tests run by Nano Gas™ have shown that 50% of their nanobubbles remain in the water three weeks after the solution has stood open to the atmosphere at normal temperatures.

Why Do Nanobubbles Enhance Oil Recovery?

Nanobubbles have at least two unique physical characteristics broadly published in scientific literature that allow them to enhance oil recovery when they are injected downhole.

- Nanobubbles have uniform negative electric charges and stay remarkably evenly distributed throughout the liquid. As a result, they change the surface tension with other substances around them. When injected downhole nanobubbles attach to geological formations and rocks become water wet, not oil wet. As a result, the oil moves away from the formation and more readily flows to the surface.

- In addition, Nano Gas™’s nanobubbles are formed in high concentrations that become as hard as ball bearings under pressure. As a result, the tiny bubbles penetrate interstitial cracks in the geologic formation and drive out hydrocarbons similar to the way fracking does once the rock formations are opened up.

Nano Gas™ Environmental’s Progress to Date

A little over five years ago Nano Gas™ personnel recognized these two unique characteristics of nanobubbles and theorized that if pumped downhole nanobubbles could drive out more oil. The company was already active in the oil industry demonstrating that nanobubbles of nitrogen and oxygen could more efficiently and effectively process the oil industry’s dirty wastewater (produced water).

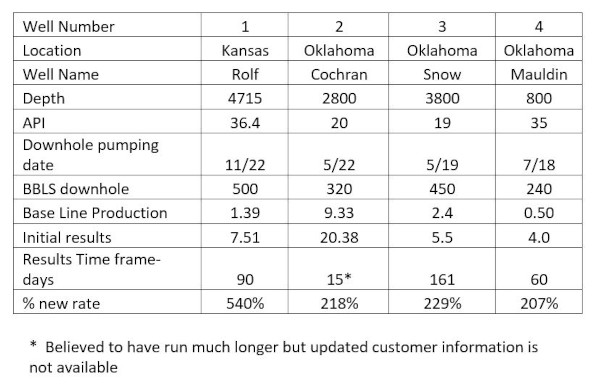

They leveraged their industry connections and in July 2018 ran an initial downhole test of nitrogen nanobubbles to enhance oil recovery. That initial test in Oklahoma doubled the production rate of an 800-foot vertical well for 60 days. The company subsequently ran Amott cell tests that proved the nitrogen nanobubbles would lift the oil.

Following that initial downhole test, the company and its agents ran additional downhole demonstrations the results of which are shown below. The most recently concluded Nitro- Nano™ EOR injection was paid for by the customer. It has been producing for 90 days and the customer is pleased with the results. As shown below, Nano Gas™ has demonstrated its ability to Enhance Oil Recovery in vertical wells ranging from 800 feet to 4800 feet producing crude oil with APIs between 19 and 36.

The process involves removing saltwater, usually with a biocide in it, from a frack tank or tank truck and passing that water through Nano Gas™’s patented nano bubble production unit. The unit uses nitrogen from a nitrogen bottle or from the air to produce nitrogen nanobubbles in the water and then puts the water back into the tank for injection of the highly concentrated nanobubbles into the well. The fluid penetrates the formation for several days before the well is turned back on.

The process involves removing saltwater, usually with a biocide in it, from a frack tank or tank truck and passing that water through Nano Gas™’s patented nano bubble production unit. The unit uses nitrogen from a nitrogen bottle or from the air to produce nitrogen nanobubbles in the water and then puts the water back into the tank for injection of the highly concentrated nanobubbles into the well. The fluid penetrates the formation for several days before the well is turned back on.

Because the process uses existing salt water and naturally occurring nitrogen it is far more environmentally friendly than traditional oil recovery methods that rely on energy intensive steam, chemicals or carbon dioxide injection.

The company also initiated activities to patent their discovery. US patent number 11,585,195 B1 was issued on February 21, 2023. That patent, when combined with company’s previously issued production patents and know-how puts them in a unique position to serve the oil industry. There are five known ways to make nanobubbles and tests have shown that Nano Gas™’s production process is the only one with these unique advantages over other production methodologies:

- Nano Gas™ utilizes a patented production process that makes higher concentrations of nanobubbles than any other method. For other nanobubble producers to attempt to duplicate Nano Gas™’s downhole success tests have shown that at least seven passes are sometimes necessary.

- Furthermore, the most predominant method involves making nanobubbles with membranes. This process requires very clean water to prevent the membranes from plugging and stopping production.

These advantages make Nano Gas™’s process particularly valuable and unique when using nanotechnology for EOR. Nano Gas™ also has broad experience using multiple gases including air, oxygen, nitrogen and carbon dioxide to make nanobubbles. The company has in-depth knowledge of which gases will work best for EOR. Most other producers have focused solely on using oxygen.

Nano Gas™’s Future Plans

The recent commercial EOR activities in Kansas were conducted with the original alpha unit the company used to conduct its initial tests in 2018. Since that time, that unit has been automated so it runs without ongoing human attention, but the basic parameters of its operation are the same and not as well suited to commercial EOR activities as they should be.

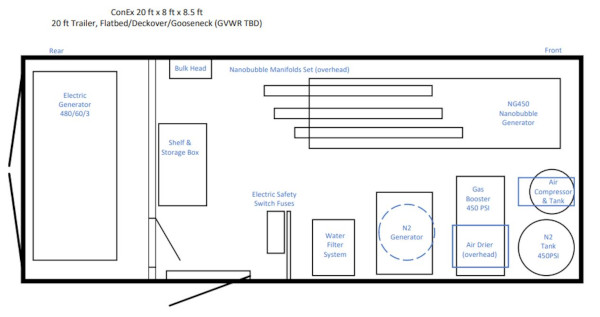

The new fully automated NG 450 EOR unit shown in the sketch below is an integrated mobile system specifically designed for EOR. It will produce 500 barrels of Nitro Nano™ EOR fluids in 8 hours, nearly 5 times faster than the alpha unit. It will have an onboard nitrogen generator, eliminating manual changeout of 5 bottles per well, and will carry its own diesel powered 460V/3 phase generator, instead of using an external generator that requires a second truck or trip. As a result, the company anticipates being able to produce enough Nitro- Nano™ fluids to treat up to six wells per week when the unit is fully staffed.

The company is also prepared to establish a centralized distribution set up. A continuously run NG 450 EOR unit will connect to site resident power without the generator. A storage tank will receive Nitro Nano™ infused water prior to its being transported by tank truck to the well and then pumped downhole. Given the fact that nano bubbles can sit for days without any loss in their potency, the process of using a static tank and mobile delivery vehicles is highly feasible and more cost-effective for large users that have geographically concentrated well facilities.

The company is also prepared to establish a centralized distribution set up. A continuously run NG 450 EOR unit will connect to site resident power without the generator. A storage tank will receive Nitro Nano™ infused water prior to its being transported by tank truck to the well and then pumped downhole. Given the fact that nano bubbles can sit for days without any loss in their potency, the process of using a static tank and mobile delivery vehicles is highly feasible and more cost-effective for large users that have geographically concentrated well facilities.

For more information and videos of the original EOR process go to the company’s website, nanogasenvironmental.com or view https://youtu.be/ZSycGJjXyBg.